Please tell us

about your dream.

Having started as a cosmetics planning company, we have grown into an OEM manufacturer by establishing our own factory.

Based on the belief that "manufacturing fulfills dreams", we respond to diverse customer requests and develop products using unique and original technology and ideas.

Whether you've given up on a dream you thought was unattainable, or are unsure of where to begin, please feel free to consult with us. Let's work together to help your dream take shape.

Manufactured by INTCO

Manufactured by INTCOClick here to purchase AI Nitrile Gloves

You want to create an original cosmetics product but are unsure of where to turn.

We manufacture a wide range of items, from original cosmetics to specially formulated cosmetics developed with doctors, hair care products, and original fragrances.

In addition, we offer comprehensive support, including help in selecting a container that aligns with your vision, label and packaging design, and regulatory compliance procedures.

Beyond product creation, you might be unsure of what steps to take next.

It's easy to overlook the importance of choosing the right brand name in product development.

Choosing a name that's already trademarked or that conflicts with the Pharmaceutical Affairs Law can have serious consequences, including the inability to sell your product.

We can also handle the trademark registration process for you, ensuring everything is properly taken care of.

You might be wondering if products made through an OEM will actually be successful in the market.

From our own factory's production to marketing, sales strategies, and distribution, we have the comprehensive know-how to help ensure your product's market success.

We also leverage the latest marketing techniques, including professional product photography in our own studio and engaging live commerce presentations, to maximize your brand's visibility and impact.

Our streamlined, one-stop marketing approach helps you achieve your business goals.

Cosmetics OEM/ODM

For OEM and ODM manufacturing of cosmetics and health foods, AMPLY is the name you can trust.

We have extensive experience and expertise in bringing a wide range of products to life, from original cosmetics and specially formulated cosmetics developed with doctors to hair care products, fragrances, and even health foods made with domestically sourced ingredients.

From initial concept to development, delivery, and even onward to distribution and sales, we offer comprehensive support every step of the way. So even if you're new to OEM/ODM manufacturing, don't hesitate to contact us.

The Process of Creating Your Cosmetic Product

-

Initial Consultation

We will discuss the specifics of your desired product, including product image, production quantity, budget, and desired delivery date, and we will offer a proposal based on this discussion.

-

Formulation, Prototyping, and Development

Based on the concept discussed, we will formulate and develop prototypes, presenting you with a sample that meets your expectations.

-

Finalizing Product Specifications

Even the choice of container involves many considerations, such as compatibility with the product formula, design aesthetics, and dispensing volume.

We will help you select a container that aligns with your vision. -

Trademark Registration

We can also handle the trademark registration process for you, protecting your valuable product name.

-

Packaging Design Proposals

We also offer packaging design proposals for clients who request them, helping to alleviate any concerns you may have if this is your first time developing a product.

-

Ordering and Manufacturing

Once you approve the quote, we will begin manufacturing.

You can rest assured that we handle all necessary procedures in accordance with the Pharmaceutical Affairs Law. -

Delivery

We will deliver the finished product to you.

-

Sales and Distribution Support

We provide expert guidance based on our extensive sales track record.

We offer support and guidance on various sales channels, including e-commerce, overseas sales, and live stream broadcasts.

Container Development Services

We cater to a wide range of needs, from basic containers to custom-designed original containers. We provide comprehensive, one-stop support, from container selection and development to container design. When it comes to containers, you can count on us.

PET Pump Bottles

Airless Containers

PET Lotion Bottles

UV-Protective Containers

Cream Jars

Shampoo Bottles

Dropper Bottles

Tubes

Pump Foamer Bottles

Glass Cream Jars

Glass Pump Bottles

Glass Lotion Bottles

Laminate Tubes

Multifaceted Promotions Created

by AMPLY and RHYTHM

AMPLY, together with its group company RHYTHM Inc., offers a comprehensive promotion business that leverages their extensive experience and network in the beauty industry.

Through multifaceted approaches, including engaging content creation, social media management, real-time product introductions via live streaming, and media development both domestically and internationally, we disseminate our clients' brands to the world.

By crafting messages that resonate with the target audience, we contribute to increased sales.

What AMPLY Can Do

-

Marketing

-

Sales Strategy/PR

-

Distribution

-

Sales Website Development

/Management

The Manufacturing Floor

AMPLY Chiba Factory

The AMPLY Chiba Factory began operations in 2005.

Using original formulations, we create skincare and hair care products, and other cosmetics that reflect our customers' visions. We offer one-stop support, from formulation development and regulatory compliance procedures to help in selecting packaging and final product delivery.

Itako Logistics Center

The center has a vast truck yard and is capable of devanning large volumes of goods, including those from 10-ton trucks and overseas shipping containers.

As an Ibaraki-based company, we value our connection with the local community and are committed to contributing to its revitalization through social contribution activities.

AMPLY Chiba Factory

The Product Completion Process

Manufacturing the Product Formula

We use only raw materials that meet our strict quality standards, and we manufacture the product formula according to precisely defined methods, procedures, and conditions for each product.

At AMPLY, our experienced formulation and process designers work closely with our highly skilled manufacturing staff, ensuring precise and consistent compounding that perfectly matches the design specifications.

Product Formula Inspection

Every batch of product formula undergoes thorough testing, in accordance with the specific standards set for each product.

This includes careful sensory evaluations (color, fragrance, texture), physical property measurements (pH, viscosity, specific gravity, etc.), and microbial testing (total viable count, and detection of specific microorganisms).

These tests are carried out with consideration for both our clients' expectations and the end-users' usage patterns.

Filling

Just like in the manufacturing of the product formula, the filling process is also subject to rigorous quality control.

We use specialized equipment tailored to the specific characteristics of each product formula, container shape, and production run size, ensuring accurate fill volumes and proper cap torque. We don't rely entirely on automation, and our staff also performs manual checks as needed, as we are committed to continuous quality improvement, including preventing any foreign object contamination.

Finishing and Packaging

Our skilled staff meticulously handles the finishing touches, such as precise label placement and careful packing into presentation boxes. We strive to meet our clients' specific requests, such as "I'd like this kind of design" or "I want a unique label," and we are dedicated to ensuring the satisfaction of both our clients and the end-users.

Shipping

After thorough quality inspections of the finished products, including visual checks for any scratches or imperfections and functional tests of the containers, as well as a comprehensive review of all manufacturing records, we deliver safe and reliable cosmetics to our customers.

Itako Logistics Center

Role of the Itako Logistics Center

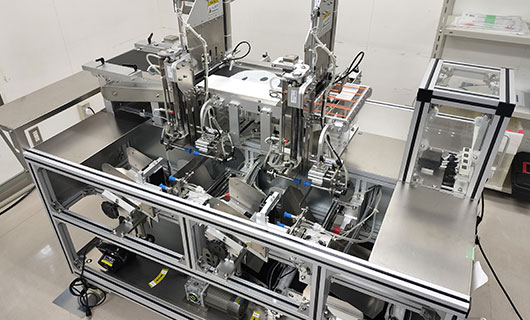

Face Mask Filling

We use a custom-made filling machine specifically for face masks, manufactured by a partner machinery manufacturer. By producing the formula in-house, we're able to offer cost-effective products starting from small lots. We provide fast turnaround from product launch to delivery.

Face Mask Weaving Machine

We use a custom-made weaving machine specifically for face masks, manufactured by a partner machinery manufacturer.

It can handle a wide variety of shapes, from basic non-woven fabrics to character-themed designs, and we can accommodate orders starting from small lots.

We also accept requests for only the folding process of non-woven fabrics.

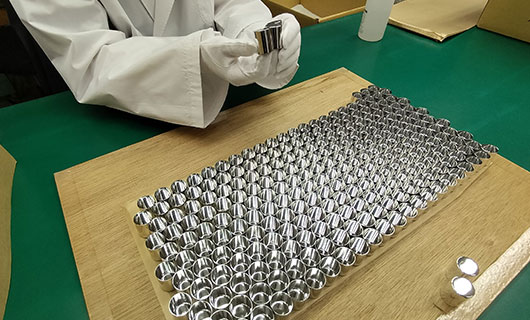

Inspection, Finishing, and Packaging

We conduct inspections of cosmetic containers and assemble beauty devices, miscellaneous goods, and other products, all under our strict quality standards.

In addition to large-lot production for general retail, we also offer manufacturing agency services tailored to individual customer requests.

Gold Crown Cap Finishing

We inspect gold crown caps for cosmetics, meticulously checking each one for scratches, plating defects, dents, and other imperfections.

After inspection, adhesive is applied to the inside of the gold crown cap, and a turntable is used to attach it to a plastic cap, completing the cap assembly.

Warehousing, Shipping, and Receiving

We manage the warehousing of products using a location management system and ship them to aesthetic clinics, drugstores, clinics, and beauty salons nationwide.

Upon request, we can also arrange for large charter shipments and container vanning.

Industrial Chemical Products Division

When it comes to gloves for everyday use, quality is paramount.

AMPLY's AI Nitrile Gloves and AI Plastic (PVC) Gloves offer exceptional quality in disposable hand protection.

We've ensured a consistent supply of these high-quality gloves at competitive prices.

Our AI Plastic Gloves are latex-free, making them ideal for those with allergies and safe for use around children. Both glove types provide reliable hand protection and a comfortable fit.

When it comes to gloves for everyday use, quality is paramount. AMPLY's AI Nitrile Gloves and AI Plastic (PVC) Gloves offer exceptional quality in disposable hand protection. We've ensured a consistent supply of these high-quality gloves at competitive prices.

-

AMPLY AI Nitrile Gloves

-

AI Plastic (PVC) Gloves

-

AI Surgical Masks

Company Profile

| Company Name | AMPLY Co., Ltd. |

|---|---|

| Date of Establishment | February 1996 |

| Capital | ¥30 million |

| Chairman of the Board | Mitsumasa Tani |

| President | Makoto Okumura |

| Senior Managing Director Managing Director Director Executive Officer Executive Officer Executive Office |

Jun Shinoda Satoru Hori Masanobu Ishibashi Kiyotaka Taira Minoru Morozawa Sachiko Kitamura |

| Senior Managing Director | Jun Shinoda |

| Managing Director | Satoru Hori |

| Director | Masanobu Ishibashi |

| Executive Officer | Kiyotaka Taira |

| Executive Officer | Minoru Morozawa |

| Executive Office | Sachiko Kitamura |

| Business Activities | Planning, development, and manufacturing of cosmetics, quasi-drugs, and health foods. Wholesale of cosmetics, health foods, and beauty equipment. Planning, development, and production of cosmetic containers and packaging. Planning, development, and production of novelty goods. Sales of HAGY-related products. Cross-border business support for expansion into China (and other Asian regions). |