CHIBA FACTORY

AMPLY Chiba Factory

CHIBA FACTORY

AMPLY Chiba Factory

AMPLY Chiba Factory started its operation in 2005. Our factory is able to manage a wide range of issues than basic manufacturing and production. We also provide other services such as basic research, formula development and special container development. Also, we are actively engaged in environmental activities such as reducing CO2 emissions and reducing waste.

Until product is made

The flow from acceptance of raw materials to shipment is strictly controlled, and there are strict standards not only for quality inspection but also for the manufacturing process, and only products that have cleared all of these steps are delivered to customers.

Acceptance of raw materials

We only accept raw materials that pass strict evaluation standards.

(The photo shows equipment that produces skin care products such as skin lotion.)

Production of contents

We conduct manufacturing through strictly defined methods, procedures, and conditions for each product. AMPLY manufactures consistent, superior, top grade products due to the balanced combination of skilled craftsmen working with the latest technology, machinery, and computer hardware and software.

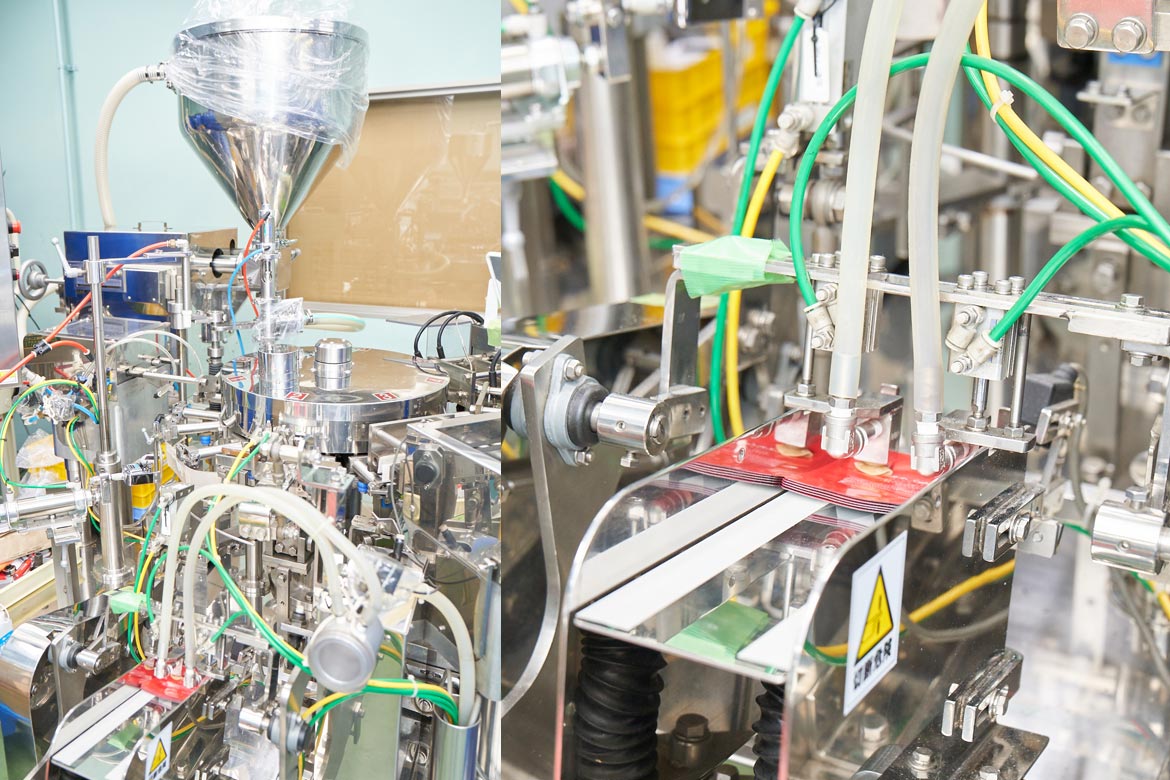

Filling

In a similar way to contents production, the filling process is strictly controlled too. Skin care products have completely different filling and finishing methods depending on the characteristics and specifications, so we use equipment that suits each product.

(The photo shows filling and packing equipment for CO2 Gel Pack.)

Filling

We don’t leave everything up to the machines. We use human hands as necessary, and finish it one by one carefully.

(The photo shows filling equipment for beauty essence.)

Container manufacturing

Also, AMPLY manufactures containers that fill the manufactured bulk items.

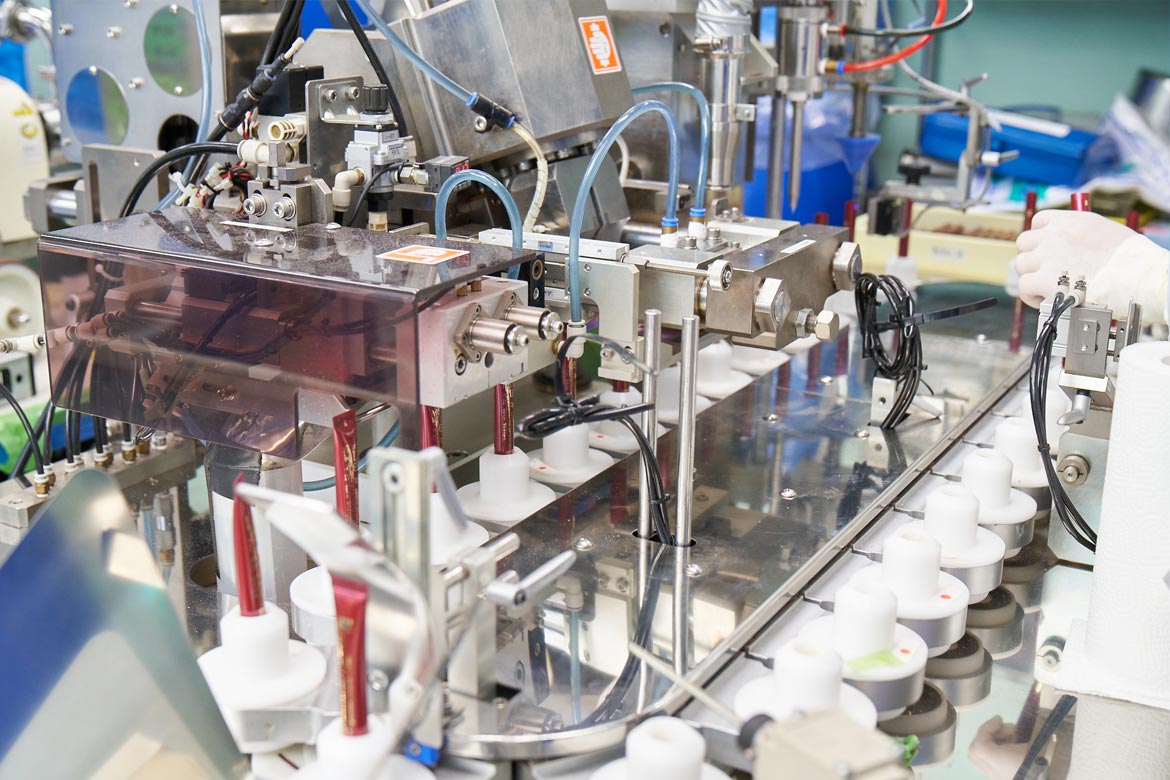

(The photo shows manufacturing line for containers to filling face cream.)

Container quality control

Before filling the manufactured bulk, we carefully inspect each container with the human eye one at a time.

Quality examination

We conduct quality inspections such as sensory inspection, physical and chemical inspection, and microbiological inspection to produce and ship safe and secure products.

Acceptance of raw materials

We only accept raw materials that pass strict evaluation standards.

(The photo shows equipment that produces skin care products such as skin lotion.)

Production of contents

We conduct manufacturing through strictly defined methods, procedures, and conditions for each product. AMPLY manufactures consistent, superior, top grade products due to the balanced combination of skilled craftsmen working with the latest technology, machinery, and computer hardware and software.

Filling

In a similar way to contents production, the filling process is strictly controlled too. Skin care products have completely different filling and finishing methods depending on the characteristics and specifications, so we use equipment that suits each product.

(The photo shows filling and packing equipment for CO2 Gel Pack.)

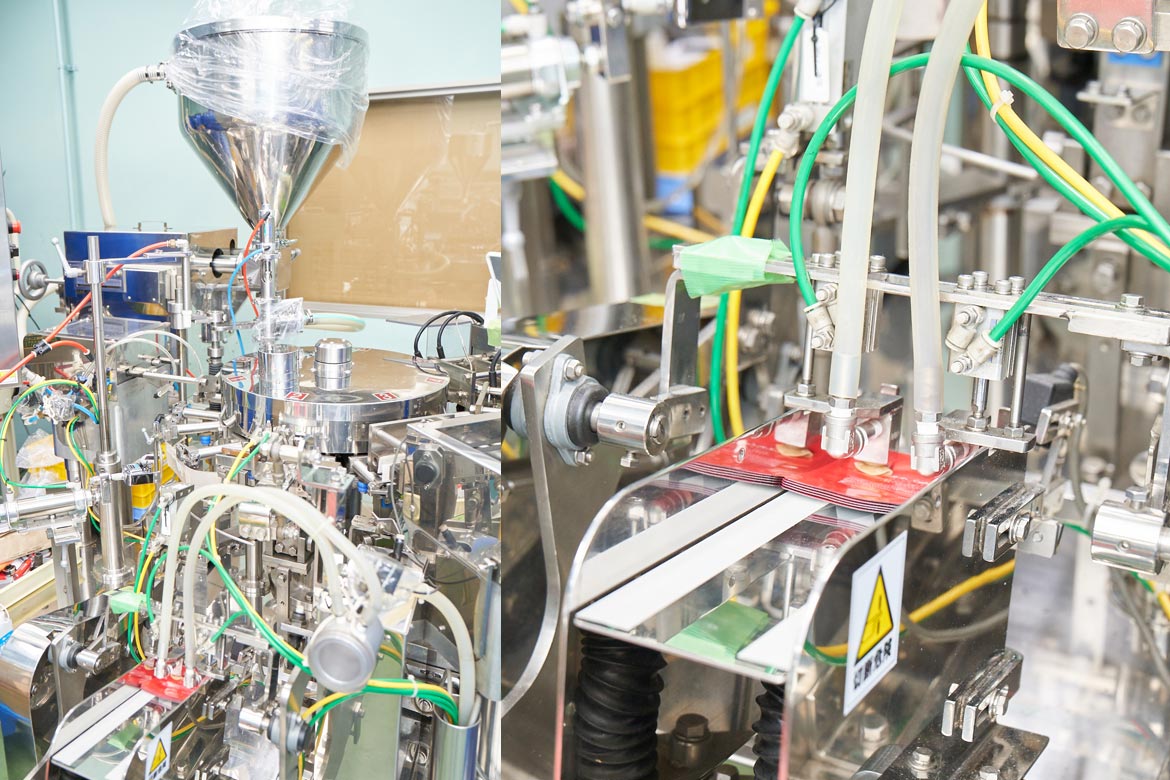

Filling

We don’t leave everything up to the machines. We use human hands as necessary, and finish it one by one carefully.

(The photo shows filling equipment for beauty essence.)

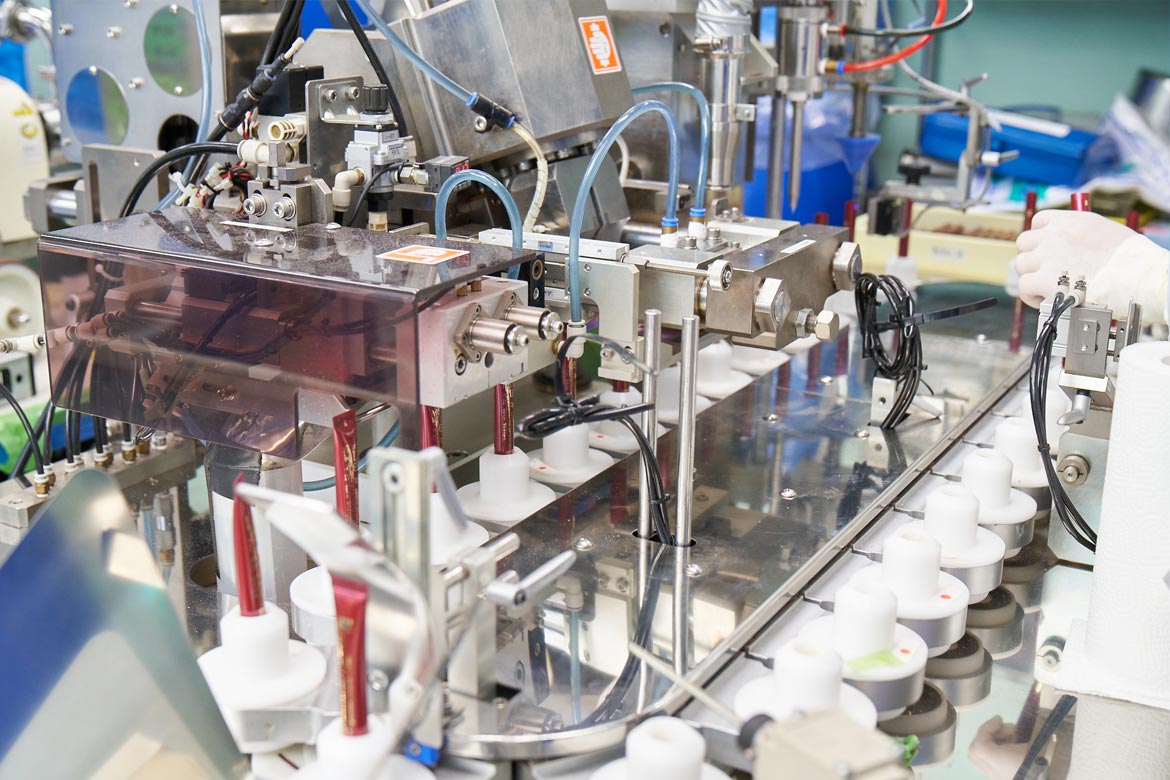

Container manufacturing

Also, AMPLY manufactures containers that fill the manufactured bulk items.

(The photo shows manufacturing line for containers to filling face cream.)

Container quality control

Before filling the manufactured bulk, we carefully inspect each container with the human eye one at a time.

Quality examination

We conduct quality inspections such as sensory inspection, physical and chemical inspection, and microbiological inspection to produce and ship safe and secure products.

Strict quality control

Thorough complying with all AMPLY’s original quality control regulations, we accomplish with strict quality control. Employees repeatedly change their clothes, properly wash hands, and use special air showering chambers to remove dust at any time of entering and exiting the weighing, manufacturing, and filling zones, in order to keep the factory clean, and keep our products pure.

Packaging

The filled product is packaged in a form of product that is delivered to the customer’s hand.

Strict quality control

Thorough complying with all AMPLY’s original quality control regulations, we accomplish with strict quality control. Employees repeatedly change their clothes, properly wash hands, and use special air showering chambers to remove dust at any time of entering and exiting the weighing, manufacturing, and filling zones, in order to keep the factory clean, and keep our products pure.

Packaging

The filled product is packaged in a form of product that is delivered to the customer’s hand.

CONTACT

お問い合わせ

CONTACT

お問い合わせ